Having any experience in the manufacturing industry, it is not uncommon to come across clients who have preconceived notions about robotic technology, thus promulgating certain misconceptions when there is an intent to implement cobots into their manufacturing systems.

Take, for instance, how the various types of manufacturing factories, such as automobile companies or toy production chains, respectively utilize diverse sets of robotic technology. Even within these niche fabrication industries, there can be a multitude of automated manufacturing technologies implemented. However, to business decision-makers, these intricacies can often be alien to them – what matters is the results of automation.

That said, the distinctions between collaborative robots versus industrial robots are much more apparent upon certain parameters. To simplify the common misconceptions about cobots, we’ll have to look at three key factors:

- Capacity

- Safety

- Programming

What Are Cobots?

Cobots, by definition, refer to collaborative robots, and these machines serve to work on specific jobs alongside human employees. So, to easily distinguish a cobot from an industrial robot is to look at the way a robot is designed to function.

Industrial-type robots often replace the function of human workers in an assembly line, while cobots are put in place to take over the dangerous, tedious, or high-stress processes in assisting human workers.

Misconception #1: Collaborative Robots are Cost-Effective Industrial Robots

Cobot integration, in its entirety, introduces a safer and more efficient production line for workers, consequently resulting to better productivity and work satisfaction for the team. Industrial robots, on the other hand, introduce productivity by way of automation as well, aiming to replicate the entire manufacturing process with barely any human intervention. So, with automation as its foremost benefit, the blurred distinction between collaborative and industrial robots as one and the same is indeed a common misconception.

When it comes to capacity, it has to be made clear that cobots are not intended to replace factory workers, which basically means that cobots are not designed to execute heavy manufacturing jobs, or even “take away” jobs in the first place. Given their function, cobots are built to work alongside workers – ideally, to address efficiency, worker health, and safety in the workplace.

For capacity concerns, industrial robots are deliberately designed to handle heavy manufacturing jobs. Cobots should not be viewed as cost-effective alternative towards automation in lieu of industrial robots. If anything, cobots can lead to unlocking higher-skilled labor opportunities.

Misconception #2: Cobots are Unsafe to Use Around Human Staff

Given their size and the functional requisite proximity to human workers, cobots cannot replace industrial machines and robots in heavy manufacturing processes, because these large-scale robots demand certain precautions and trainings to operate.

Unlike industrial robots, cobots offer a wide spectrum of safety features to function around human workers without the need for infrastructures, such as a workspace safety cage or containment area.

So, in terms of safety, the misconception that collaborative robots are unsafe to operate alongside employees is an unfortunate way to view cobots in general. It does bear noting that while cobots are much safer when compared to industrial robots, handling and operating all types of equipment come with the necessary knowledge and care to ensure worker safety.

Misconception #3: All Robotic Customizations are Costly and Problematic

Both types of robotic technologies, cobots and industrial-use, indeed offer customization. However, due to the disparity in sizing, capacities, and applications, the difference in engineering costs is worth consideration.

There are cobot brands offering pre-engineered design options that specifically address automation challenges in the workplace. These solutions, such as an external vision module for advanced vision capabilities, have been designed to reduce the necessary costs to implement innovation while immediately catering to a business need. That said, greater levels of cobot customization will still deliver more targeted approaches to automation.

Industrial-use robots, such as the ones operating in automotive manufacturing plants, deliver more complex processes – often intricate and customized to the brand’s fabrication needs – which are proportionate to the cost of engineering their product, like a vehicle.

In comparing the level of programming, cobots offer an easier solution compared to industrial robots, as the former is capable of machine learning. With AI technology, a human worker can reprogram a collaborative robot by setting the robotic arm through its new path, which the cobot remembers and repeats.

An industrial robot, on the one hand, will most likely require rewriting its code to implement process changes.

Customization in cobots can be easy, simple, and straightforward.

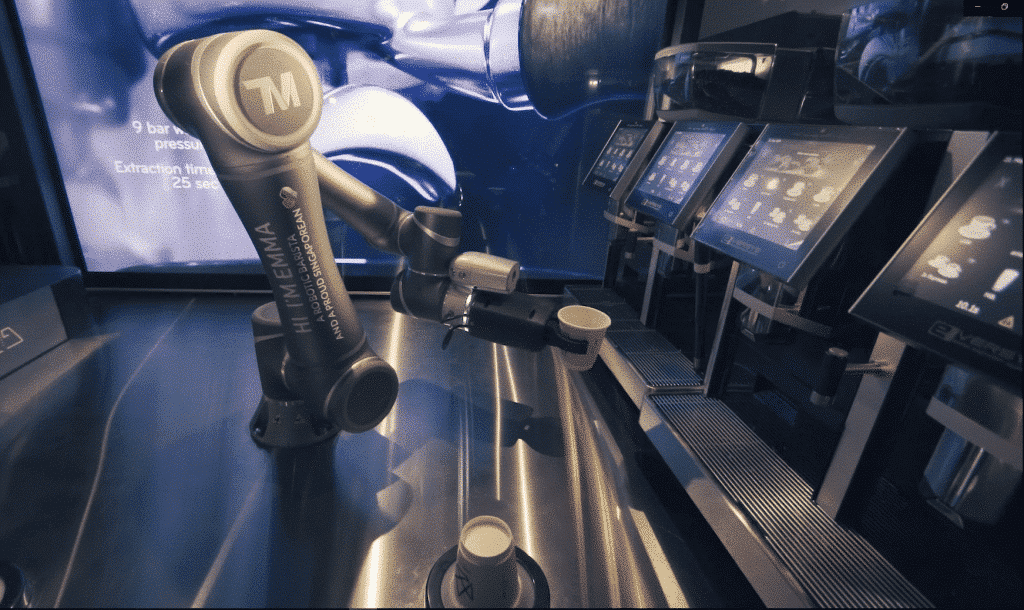

Techman Robot: Improving the World of Work with Collaborative Robots

Discover what cobots can do for a business before buying into any misconceptions. Collaborative work is relatively new, but has been gaining traction in recent years, especially with an increasing demand for automation in the manufacturing industry.

Dedicated to improving businesses worldwide through collaborative robot and vision technologies, Techman Robot is here to solve technological challenges, meet every industry’s needs, and close the gap for every business.

For more on automation, Industry 4.0, and cobot technologies, visit our resources or send us a message today.